- Regular Price

- £19.99

- Sale Price

- £19.99

- Regular Price

- £19.99

- Unit Price

- per

Synthetics, wool, or bamboo? Bamboo is now well known as an excellent performance fibre and is "green" in more than one sense of the word. So, together with all the "high tech" high performance manmade fibres available, has bamboo consigned wool to the old blanket box of history?

Since the birth of the industrial textile industry in the 19th century mankind has strived to create textiles for clothing, bedding and furnishings with better and higher performance.

Textile fibres are synthetic or natural, or structures that can be spun into a yarn and then knitted or bonded into a fabric with or without other materials. The inherent characteristics of fibres directly relate to the performance of a finished fabric and what is required to maintain it. Different textile fabric uses require different characteristics of high performance. For instance, fibre textile on seating on planes and trains have different needs from “base layer” clothing worn next to the skin or bedding to help one sleep well.

For many years wool had a bad press and remains controversial. It has often been seen as old fashioned and fuddy-duddy, difficult to care for and is now even claimed to be cruel by a small but noisy minority.

Synthetic Fibres

Regenerated fibres like rayon (viscose) and acetate, amongst the first manmade fibres, and Tencel, are made from cellulose polymers derived from usually cotton or wood pulp. These compounds are are radically altered and modified which effectively turns them from a biodegradable compound to a non-biodegradable plastic.

Wholly synthetic fibres like nylon, acrylic, polyester and polypropylene are all derived from crude oil. These textile fibres make up 60% of apparel currently in production, 85% of which is sent to landfill after only a single ownership, yet it cannot decompose. Less than 1% of consumer textiles are recycled into new clothing.

What, then of the performance of synthetic fibres?

Elastane (Lycra, Spandex): Super stretchy. Used in stretchy sports gear, swimsuits, motion capture suits in the film industry. Also used in wool socks, even those with very high wool percentages, to help keep their shape. Elastane is entirely synthetic and made from polyurethane.

Acrylic: strong and elastic. It can be made into a good insulator if a crimp is added during manufacture, but has very poor absorbency, so will often feel too hot or wet and clammy against the skin.

Polyester (PET): is durable and elastic. It's used in apparel, homewares, water bottles and many plastic items in industry. Relatively UV stable, it is high wicking, but has poor absorbency. Is usually blended with other textiles to improve comfort.

Polyamide (Nylon, Kevlar): This covers a range of fabrics. Non-breathable, non-insulating, high pilling, strong, silky and highly elastic. Can be made very fine e.g., for stockings. Nylon was originally developed for parachute production in World War II and found a second life in women's dresses. It is vastly improved by blending with natural textiles which it lends durability and elasticity.

Polypropylene (polypro): Extremely light weight, completely non-absorbent of water, so is high wicking - water readily evaporates off it. It does not accept dye, but it absorbs body odours instead so requires frequent washing. Low melting point and not UV resistant, needs to be washed cool.

Pollution

These fibres are often cheap to make, but industrial processes are carbon intensive and the waste problem of manmade fibres is completely out of control. It has been found that around 700,000 microplastic fibres can be released into from a single domestic laundry cycle into waste water and often into the sea.

Bamboo

Bamboo, the “new” wonder fibre! It’s pretty much a magical product in terms of performance. Against all synthetics it is unparalleled. Bamboo is actively antibacterial (effectively for ever). It is durable and hard-wearing yet softer than cotton, with excellent drape. Being anti-static, it doesn't cling to the body. It is highly breathable, strong, takes a dye well and, containing no microplastics, it is entirely biodegradable. What's not to love?

Bamboo has been used in fabrics for many centuries but is only more recently seen as a mainstream apparel fabric in the West. However, in terms of sustainability, it is your proverbial mixed tote bag.

70% of bamboo product comes from China, where it’s been grown for thousands of years, with countries like Indonesia and Vietnam now also significant exporters.

At up to three-feet in a day, bamboo is the fastest growing woody plant on Earth (a third faster than the fastest growing tree) and, uniquely, needs little to no fertiliser, pesticides or other chemical inputs for cultivation. Through a process called phytoremediation as it can be used to remove pollutants from water, soil and even air. It binds the soil, it captures more carbon than a similar area of trees and because it doesn’t need uprooting upon harvesting it is effectively no-dig, which helps preserve soil ecosytems.

However, the ever-growing demand for bamboo, which has more than doubled since the year 2000, has led to the destruction of natural forests for bamboo crops. From a biodiversity standpoint, that is more that somewhat unsustainable.

Why is bamboo fibre production not sustainable? Remember our Three Pillars of Sustainability?

Already big business in China, it was reported in 2018 that the industry was worth around $60 billion and, because it’s primarily grown in a country where supply chains are almost impossible to trace and human rights abuse in the textile sector has been a major issue in recent years, it’s impossible to claim that Chinese bamboo is grown and harvested ethically or sustainably.

The chemical process of creating bamboo textile using carbon disulfide is extremely toxic. Chronic exposure to carbon disulfide causes nervous system and reproductive system damage and has been linked to a host of health problems. Outlawed in many western countries, these processes can be murderous. Paul David Blanc says in his "Fake Silk, The Lethal History of Viscose Rayon",“For workers in viscose rayon factories, poisoning caused insanity, nerve damage, Parkinson’s disease, and increased risk of heart disease and stroke.”

“If we look at the risk involved [with bamboo], it’s not only from a social and human rights perspective, but also from an environmental perspective,” says Megan Stoneburner, Director of Materials at Textile Exchange. “We don’t have visibility and transparency down to the farmer level. That’s a huge concern… We don’t have exact data, nor do we have the certifications to steer best practices of growing bamboo.”

Bamboo fibre fabric has so much to offer, yet it has a long way to go before it can be claimed to be truly sustainable. It needs to come from a trustworthy and sustainable source, avoiding the terrible toxicity of current production methods.

So the search for a sustainable performance fabric is still on…

What we need is a fibre that can be spun into a yarn that can do everything that bamboo can do - whilst avoiding the death and destruction of the workers who produce it. What is needed for the ultimate performance fibre for, say, apparel?

Required properties are antibacterial, durable, soft with excellent drape and without clinging, breathable, able to take a dye well and be biodegradable. It would be great if it also had these properties...

Fire retardancy, Easy care (machine wash at sustainable temperatures up to 30/40℃), Requiring minimal laundering (energy and water use), non-polluting (readily bio-degrades and does not shed microplastics).

Bamboo can do much of this, many manmade fibres each achieve a few of these characteristics, but, strangely, only wool achieves them all.

Perhaps it's because Mother Nature has been improving wool for three million years and we've only been inventing fibres for a hundred...

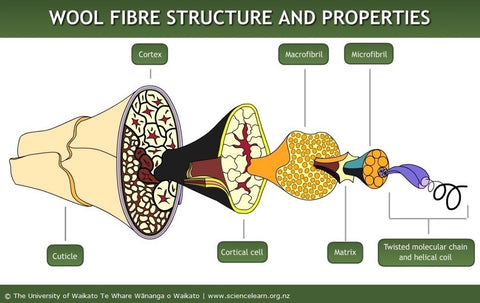

Wool is a spectacularly complex fibre.

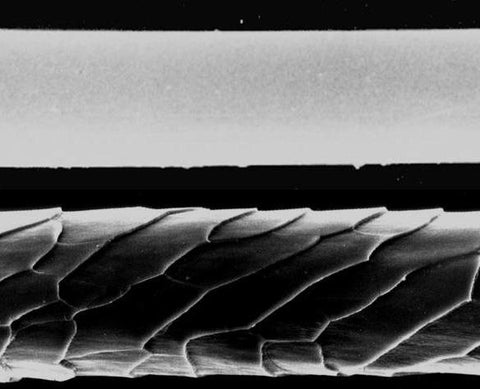

Microscopic view of smooth surface of synthetic fibre (top) and wool fibre with scaly cuticle

Cuticle: dyes and moisture penetrate the membrane and it’s this which enables a wool fibre to absorb humidity. Scaley surface protects the fibre from dirt and facilitates felting.

Cortex: this makes up 90% of the fibre. Millions of cells bind tightly together to create cortical cells.

Cortical cells: fine wool contains two main types of cells; ortho-cortical and para-cortical. Each has a unique chemical composition. These cells are essentially what gives wool its "crimp".

Macrofibril: these are the long filaments found inside the cortical cells. The macrofibrils are made up of microfibrils.

Microfibril: these are tiny twisted molecular chains: they are the supporting structures that give wool its strength and flexibility.

Matrix: this is what makes wool inherently fire-resistant, absorbent and naturally anti-static. High sulphur proteins in the matrix suck in water molecules and thus allow wool to absorb up to 30% of its own weight in water.

Twisted molecular chain and helical coil: these protein chains operate very much like springs. They give wool its flexibility, elasticity, and resilience so that it can keep its shape free of wrinkles, wear after wear and wash after wash.

Wool has been deeply studied over many years. We really can’t hope to begin to do justice here to the complex science behind wool's highly evolved structures.

If you’d like to learn more about nature’s wonder fibre, please visit

https://www.sciencelearn.org.nz/image_maps/61-wool-fibre-structure-and-properties.

Wool fibre image reproduced with the permission © The University of Waikato Te Whare Wānanga o Waikato | www.sciencelearn.org.nz)

4 comments

I understand the risks in Bamboo fibre but you did not talk about the risks in Wool which are similar: what about the sustainable growing of sheep’s, their ethical treatment is not everywhere and in all aspects free of cruelty, also because the shearer do get payed very little for each sheep because of the market, same with Lamas , Kashmir etc. If this could be solved – perfect and I would wish!

Absolutely fascinating article. Thanks.

This is great!

Though I found two typos…

Required properties… Should be if not it

Synthetic fibres…are are

However, the ever…should be than not that

You could also add that the micro fibres of synthetic fibres when washed get into the rivers and ocean and harm fish etc.

Great blog.